Tuning Resources |

Exhaust

Suggestions |

| Engine Swaps | Early Hemis | Back to Tech Links |

Tuning Tips

Keeping your engine tuned is beneficial in many ways. Not only does it

reduce the burden on one's pocketbook in regards to fuel savings, but a

good tuneup also reduces tailpipe emissions. Below is information you may

find helpful in tuning your Dodge Truck.

This first article titled Timing is Everything was

taken from HOT ROD Magazine's Brutally Basic Tech section of the April

1997 issue.

Timing is Everything

How to Set Ignition Timing

There are two things an engine must have; spark and fuel. The proper amount of

fuel and air compressed at the ideal moment produces power. In this piece we

deal with igniting the spark that lights the fire.

Ignition timing is typically split into three types. The first is ignition

timing that is, the amount of spark lead that is set using a timing light

(aimed at the harmonic balancer with the engine at idle). The second type is

mechanical advance, determined by the distributor's mechanical advance system.

The final type is vacuum advance, determined by the vacuum canister attached

to the distributor. All three combine to produce the total amount of ignition

timing in your engine at any given load and/or rpm.

Since a mechanical distributor is still the most popular form of ignition,

we'll focus on it. But before we set these values, it's important to

understand how these events interact. Initial advance is set by moving the

distributor in the engine. Once initial timing is set, it's complemented by

the mechanical and vacuum advance curves.

Mechanical advance adds additional timing to the engine and is based strictly

on rpm. The mechanical advance weights and springs inside the distributor

combine to produce a curve that begins with initial timing (with the engine

at idle) and increases to a certain rpm, but generally peaks below 3,000 rpm.

This is often referred to as the mechanical ignition curve.

Vacuum advance also adds timing to the engine, hut it is based on engine load

and is controlled by intake manifold vacuum. When the throttle is partially

open (highway cruising), manifold vacuum is high. This vacuum signal is routed

to the distributor and "pulls" on the vacuum advance canister to create more

ignition timing. As the throttle opening increases, load increases and

manifold vacuum decreases. At wide open throttle (WOT), manifold vacuum is at

or near zero and the vacuum advance produces no additional ignition timing.

Vacuum advance also adds timing to the engine, hut it is based on engine load

and is controlled by intake manifold vacuum. When the throttle is partially

open (highway cruising), manifold vacuum is high. This vacuum signal is routed

to the distributor and "pulls" on the vacuum advance canister to create more

ignition timing. As the throttle opening increases, load increases and

manifold vacuum decreases. At wide open throttle (WOT), manifold vacuum is at

or near zero and the vacuum advance produces no additional ignition timing.

Images from HOT ROD Magazine.

Now that we know how these three systems work, let's look at a real-world

example. Our fictitious engine is a small-block V-8, any V-8, but these

variables interact the same with all engines. Let's give the motor 8 degrees

of initial timing, as observed with a timing light. A test on the distributor

machine reveals 28 crankshaft degrees of total mechanical advance (at 2,800

rpm) and another 14 degrees of vacuum advance. By adding all three values, we

can see that at 2,800 rpm at light throttle (14 inches or more of manifold

vacuum), the engine has 50 degrees of total ignition advance. At WOT at 2,800

rpm, however, the engine only has 36 degrees of total timing (50 degrees minus

14 of vacuum advance).

Now that we know how these three systems work, let's look at a real-world

example. Our fictitious engine is a small-block V-8, any V-8, but these

variables interact the same with all engines. Let's give the motor 8 degrees

of initial timing, as observed with a timing light. A test on the distributor

machine reveals 28 crankshaft degrees of total mechanical advance (at 2,800

rpm) and another 14 degrees of vacuum advance. By adding all three values, we

can see that at 2,800 rpm at light throttle (14 inches or more of manifold

vacuum), the engine has 50 degrees of total ignition advance. At WOT at 2,800

rpm, however, the engine only has 36 degrees of total timing (50 degrees minus

14 of vacuum advance).

The photos illustrate how to go about moving the distributor and setting the

initial timing. By applying a timing tape to the harmonic balancer, for

example, you can set initial timing with a standard timing light and check

total timing as well. To check only initial plus mechanical advance,

disconnect the vacuum advance.

Total timing requirements are dependent upon many variables. A typical street

engine with a compression ratio of 9.0:1 runs very well with around 36 degrees

of timing (initial plus mechanical) for a rough total of 15-55 degrees of

timing at light throttle when vacuum advance is employed. If the engine

detonates or pings under WOT reduce the timing. If it surges or pings at part

throttle, reduce the amount of vacuum advance. Experimentation with timing

can help performance, driveability, and mileage by customizing the ignition

curve to your particular application. Don't be afraid to make changes. HR

Idling By is another article taken from the April 1997 issue of HOT

ROD Magazine's Brutally Basic Tech section.

Idling By

How To Set Idle Mixture

Little things can make a big difference in how an engine performs. Street

engines spend a lot of time at idle and off idle speeds, so on carbureted

engines itís important that the idle mixture be adjusted properly. This

improves driveability, minimizes rough idle, and can provide cleaner emissions

and better fuel economy. Here's a quick look at how to set Idle mixture on a

stock or mildly modified engine.

All engines require an acceptable air/fuel ratio to run properly, even at

idle. Stock or mildly tweaked engines generally idle at 16-18 inches of intake

manifold vacuum between 750 and 900 rpm. Carburetors equipped with adjustable

mixture screws allow the tuner to change the amount of fuel delivered to the

engine creating an ideal idle mixture.

On most carburetors, turning the idle mixture screw clockwise leans the idle

mixture. Turning the screws counter-clockwise richens the mixture, If there is

a vacuum leak, it must be repaired before the idle mixture can be properly

adjusted.

All stock engines specify a certain idle speed, but generally 800-850 rpm

works well. Properly setting the idle mixture also creates the highest manifold

vacuum, so a vacuum gauge makes the task easier. The best backyard procedure

for setting idle mixture is the "idle speed drop" method. First, connect the

vacuum gauge to the manifold. Adjust the idle mixture richer or leaner until

the highest vacuum is read, once this is attained, turn the idle mixture

screws leaner until the rpm begins to drop. then turn the screws richer a

slight amount. The ideal idle mixture has now been set.

If you don't have a vacuum gauge, use a low-speed tachometer. The tach should

have a low-scale readout that is sensitive to increments of at least 50 rpm.

Use the tach to help you adjust the idle mixture screws evenly to create the

highest idle speed. If the idle speed exceeds 900-950 rpm, use the idle speed

screw to slow the engine down. then readjust the idle mixture.

This isnít a difficult procedure but it can be tough if the engine has a big

cam and low manifold vacuum. If the carburetor requires a large throttle

blade opening, modifications will be necessary (see "Curing Holley Hiccups.

HOT ROD, December '96). Otherwise, this is a simple procedure that anyone can

do in a matter of minutes. HR

Images from HOT ROD

Magazine

The location of the idle mixture screws varies with each carburetor. Most

Holly four-barrel carbs locate the idle mixture screws on the metering block

(A). On the other hand, Carter, Edelbrock, and other Weber-derived

carburetors locate the mixture screws at the front of the carb (B).

Images from HOT ROD

Magazine

The location of the idle mixture screws varies with each carburetor. Most

Holly four-barrel carbs locate the idle mixture screws on the metering block

(A). On the other hand, Carter, Edelbrock, and other Weber-derived

carburetors locate the mixture screws at the front of the carb (B).

Electronic Ignition

Have you added Electronic Ignition to your truck or purchased one fortunate

to have it already? Listed here are the sections Basic Startup and

Adjustment and Ignition Tuning for Maximum Performance taken

directly from the Mopar Performance Small Block V-8 Electronic Ignition Kit

instruction sheet and HTML formatted.

BASIC STARTUP AND ADJUSTMENT:

Note: The procedures outlined below are for tuning of the MP Ignition

Conversion Kit on all vehicles and all ignition conversions.

TOOLS REQUIRED: Distributor wrench, timing light, 3/32" allen

wrench.

- Install new spark plugs gapped at .035".

- Install spark plug wires. If you have fresh, high performance wires,

it is okay to use them again. If your wires are more than two years old,

it is strongly suggested to install a new set of high performance ignition

wires. If reinstalling old wires, remove them from the old distributor cap

one at a time and transfer them to the new cap and corresponding spark

plug. If new wires are being installed, start with the number one wire in

the same location as noted in step 3 (below) and work your way around, one

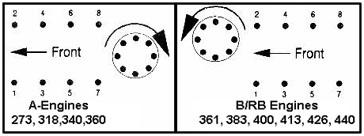

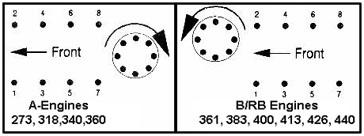

at a time. The firing order on all Chrysler V8 engines is 1-8-4-3-6-5-7-2.

The "A" engines (273-318-340-360) have clockwise distributor rotation. The

"B" (361-383-400), "RB"(413-426W-440) engines and the 426 Hemi have

counter-clockwise distributor rotation.

Image from actual instruction sheet.

Image from actual instruction sheet.

- Connect a timing light to the battery and #1 spark plug wire.

- Check to make sure that the vaccum advance hose is still disconnected

from the distributor. Temporarily plug the vaccum hose.

- Start the engine. The ballast resistor may begin to smoke after the

initial startup. This is normal, but the smoking should stop after the

engine has run for a couple of minutes.

- Set the initial timing at 5 +/- 2 degrees BTDC and tighten the

distributor hold down bolt so that the distributor housing will not

rotate. Recheck the timing setting to insure that the distributor did not

move while being tightened. Reset the timing if necessary. Disconnect the

timing light.

- Leaving the vaccum hose disconnected and plugged, test the vehicle.

After the engine is fully warmed up, make two or three throttle runs. the

runs should be made in high gear if possible. If the engine does not

have any detonation (spark knock), the initial timing setting is okay. If

the engine does detonate, reduce the initial timing by 2 degrees. Rerun

the full throttle test in high gear. Repeat this procedure until the

engine does not detonate.

- Once the initial timing setting has been completed, unplug and

reconnect the vaccum hose to the distributor. With the vaccum hose

connected, make two or three steady, part throttle runs. There should not

be any detonation, surges or hesitation in the engine. If there is, the

vaccum advance unit is adding too much advance to the spark curve. If so,

with the engine turned off, disconnect the vaccum hose. Carefully insert a

3/32" allen wrench into the fitting where the vaccum hose was connected to

the vaccum advance canister. You will be able to feel the allen wrench go

into an internal allen screw used to adjust the amount of advance provided

by the canister. Be careful not to puncture the diaphram inside the

canister. With the allen wrench plugged into the adjusting screw, turn the

allen wrench 1/2 turn (180 degrees) clockwise to reduce the vaccum advance

by approximately two to three degrees. Remove the allen wrench, reconnect

the vaccum hose and rerun the part throttle test. Repeat this procedure

until the detonation, surging and/or stumbling is eliminated.

IGNITION TUNING FOR MAXIMUM PERFORMANCE:

Tuning for maximum performance assumes the rest of the engine is also suitable

for maximum performance. The octane rating of the fuel being usedmust be

sufficient to accomidate the engine's compression ratio. The engine's harmonic

balancer must have either degree marks or timing tape which correctly

shows up to 60 degrees before top dead center. The carburetor must be properly

jetted so that detonation or surging is not caused by the fuel mixture being

too lean when the ignition is at maximum advance. The ignition coil and spark

plug wires must be able to deliver sufficient spark to fire the plugs under

maximum engine loading. If you are unsure about any of the above, consult the

Mopar Performance

Engine Modifications Manual. The manual outlines the proper ways to

construct a race engine.

If the procedures outlined for maximum performance are followed and the engine

begins to detonate, you must decrease the timing advances until the detonation

is eliminated. Detonation not only severely reduces power, it also destroys

pistons, rings and rod bearings. Do not run an engine that is detonating.

Tools required: Timing light, 3/32 allen wrench, vaccum gauge with

long hose, vaccum source ("Mighty Vac"), and a friend or helper.

1. Set the basic timing for total mechanical spark advance.

- Disconnect and plug the vaccum advance hose.

- Connect timing light to the battery and and number 1 spark plug wire.

- Loosen the distributor hold down clamp so the distributor housing may

be rotated by hand.

- Start the engine and allow it to warm up fully.

- Set the idle speed between 2600 and 2800 RPM.

- Set the timing according to the following chart:

| Engine |

Heads |

Timing Specification |

| A |

Production - Pre '89 (Iron) |

35 BTDC |

| A |

Production - '89 & Newer (Iron) |

32 BTDC |

| A |

W2 (Iron) |

35 BTDC |

| A |

W5 (Alum.) |

35 BTDC |

| B/RB |

Production (Iron) |

38 BTDC |

| B/RB |

Stage I, II, III, IV, V (Iron or Alum) |

38 BTDC |

| B/RB |

Indy (Alum) |

35 BTDC |

| B/RB |

B1 (Alum) Under 475 cu. in. |

37-39 BTDC |

| B/RB |

B1 (Alum) Over 475 cu. in., Under 15.0:1 Ratio |

36-38 BTDC |

| B/RB |

B1 (Alum) Over 475 cu. in., Over 15.0:1 Ratio |

34-36 BTDC |

| B/RB |

B1 TS |

34 BTDC |

| Hemi |

All (Iron or Alum) |

35 BTDC |

- Tighten the distributor hold down bolt.

- Reduce the idle to the original setting, unplug and reconnect the

vaccum advance line.

2. Set the vaccum advance for total ignition advance.

- After the basic timing has been set for total mechanical spark advance,

disconnect the vaccum hose at the carburetor. Connect a vaccum gauge to the

carburetor's vaccum advance port and route the gauge and hose into the

passenger compartment of the vehicle. Place the gauge in a location where an

assistant can read teh gauge while the vehicle is being operated.

- With the vehicle in operation, note the maximum amount of vaccum

generated by the engine while in gear and being held at a steady speed

between 2000 and 4000 RPM.

- Stop the vehicle, turn off the engine and connect a timing light to the

battery and number 1 spark plug wire.

- Start the engine, and raise the idle to 2600 RPM. Connect a vaccum

source (Mighty Vac) to the distributor's vaccum canister and draw vaccum up

until to the reading noted in step b.

- Note the total advance shown on the harmonic balancer.

- Total advance, mechanical plus vaccum, should be set according to the

following chart:

| Engine |

Total Advance |

| A |

50 BTDC |

| B/RB |

56 BTDC |

| Hemi |

53 BTDC |

- Disconnect the vaccum source and insert a 3/32" allen wrench into the

internal vaccum canister adjustment screw. Turn the allen screw (clockwise to

decrease, counterclockwise to increase) to obtain the correct setting.

Reconnect the vaccum souce and recheck the timing. Continue repeating this

procedure until the correct setting is obtained.

- Remove the timing light and vaccum source. Reconnect the vaccum advance

hose. Reset the idle speed to your original setting.

Please Note: This page is intended as a guide,

and is not guaranteed in any way. All info above is to the best knowledge of

the author.

Vacuum advance also adds timing to the engine, hut it is based on engine load

and is controlled by intake manifold vacuum. When the throttle is partially

open (highway cruising), manifold vacuum is high. This vacuum signal is routed

to the distributor and "pulls" on the vacuum advance canister to create more

ignition timing. As the throttle opening increases, load increases and

manifold vacuum decreases. At wide open throttle (WOT), manifold vacuum is at

or near zero and the vacuum advance produces no additional ignition timing.

Vacuum advance also adds timing to the engine, hut it is based on engine load

and is controlled by intake manifold vacuum. When the throttle is partially

open (highway cruising), manifold vacuum is high. This vacuum signal is routed

to the distributor and "pulls" on the vacuum advance canister to create more

ignition timing. As the throttle opening increases, load increases and

manifold vacuum decreases. At wide open throttle (WOT), manifold vacuum is at

or near zero and the vacuum advance produces no additional ignition timing.

Now that we know how these three systems work, let's look at a real-world

example. Our fictitious engine is a small-block V-8, any V-8, but these

variables interact the same with all engines. Let's give the motor 8 degrees

of initial timing, as observed with a timing light. A test on the distributor

machine reveals 28 crankshaft degrees of total mechanical advance (at 2,800

rpm) and another 14 degrees of vacuum advance. By adding all three values, we

can see that at 2,800 rpm at light throttle (14 inches or more of manifold

vacuum), the engine has 50 degrees of total ignition advance. At WOT at 2,800

rpm, however, the engine only has 36 degrees of total timing (50 degrees minus

14 of vacuum advance).

Now that we know how these three systems work, let's look at a real-world

example. Our fictitious engine is a small-block V-8, any V-8, but these

variables interact the same with all engines. Let's give the motor 8 degrees

of initial timing, as observed with a timing light. A test on the distributor

machine reveals 28 crankshaft degrees of total mechanical advance (at 2,800

rpm) and another 14 degrees of vacuum advance. By adding all three values, we

can see that at 2,800 rpm at light throttle (14 inches or more of manifold

vacuum), the engine has 50 degrees of total ignition advance. At WOT at 2,800

rpm, however, the engine only has 36 degrees of total timing (50 degrees minus

14 of vacuum advance).